Filter and sort

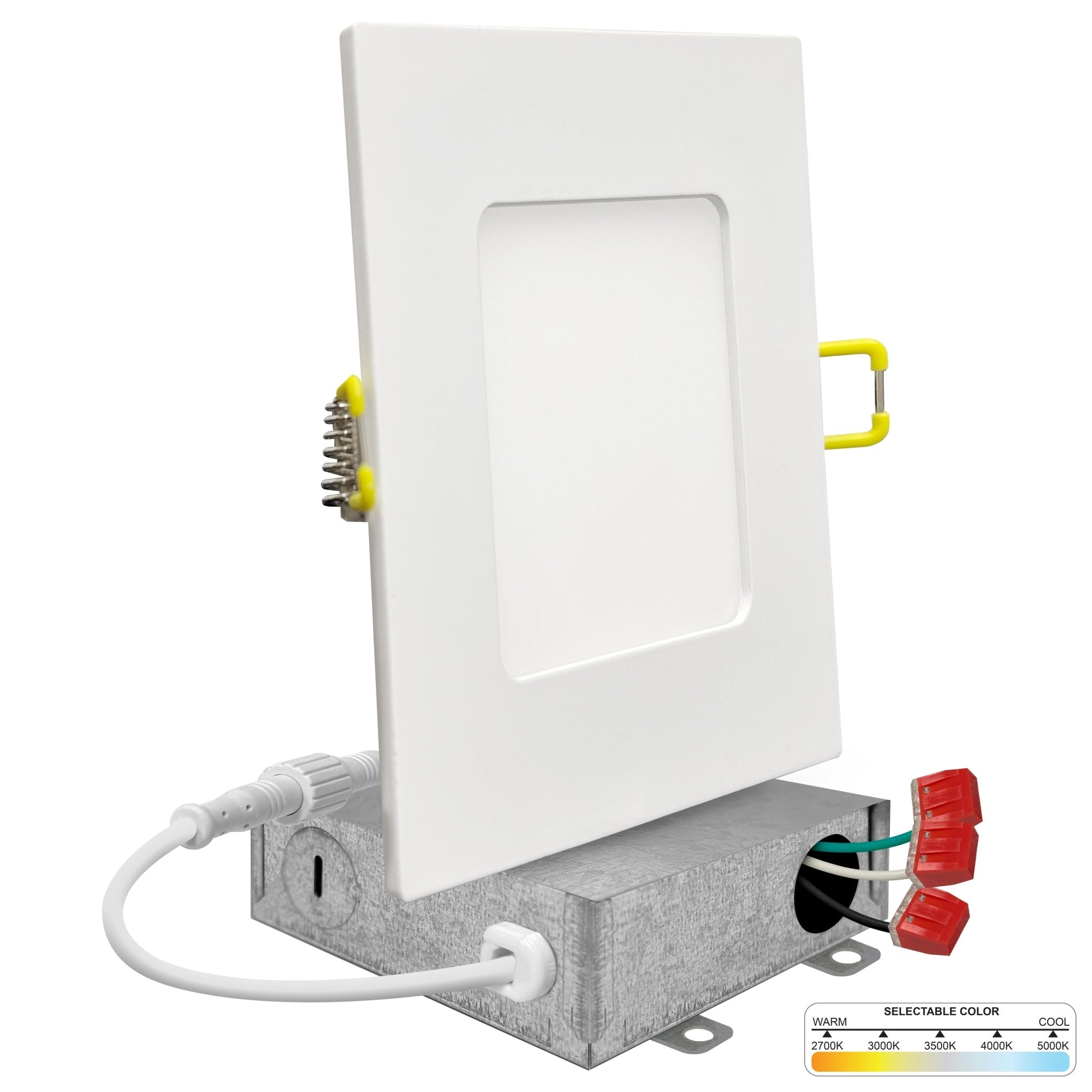

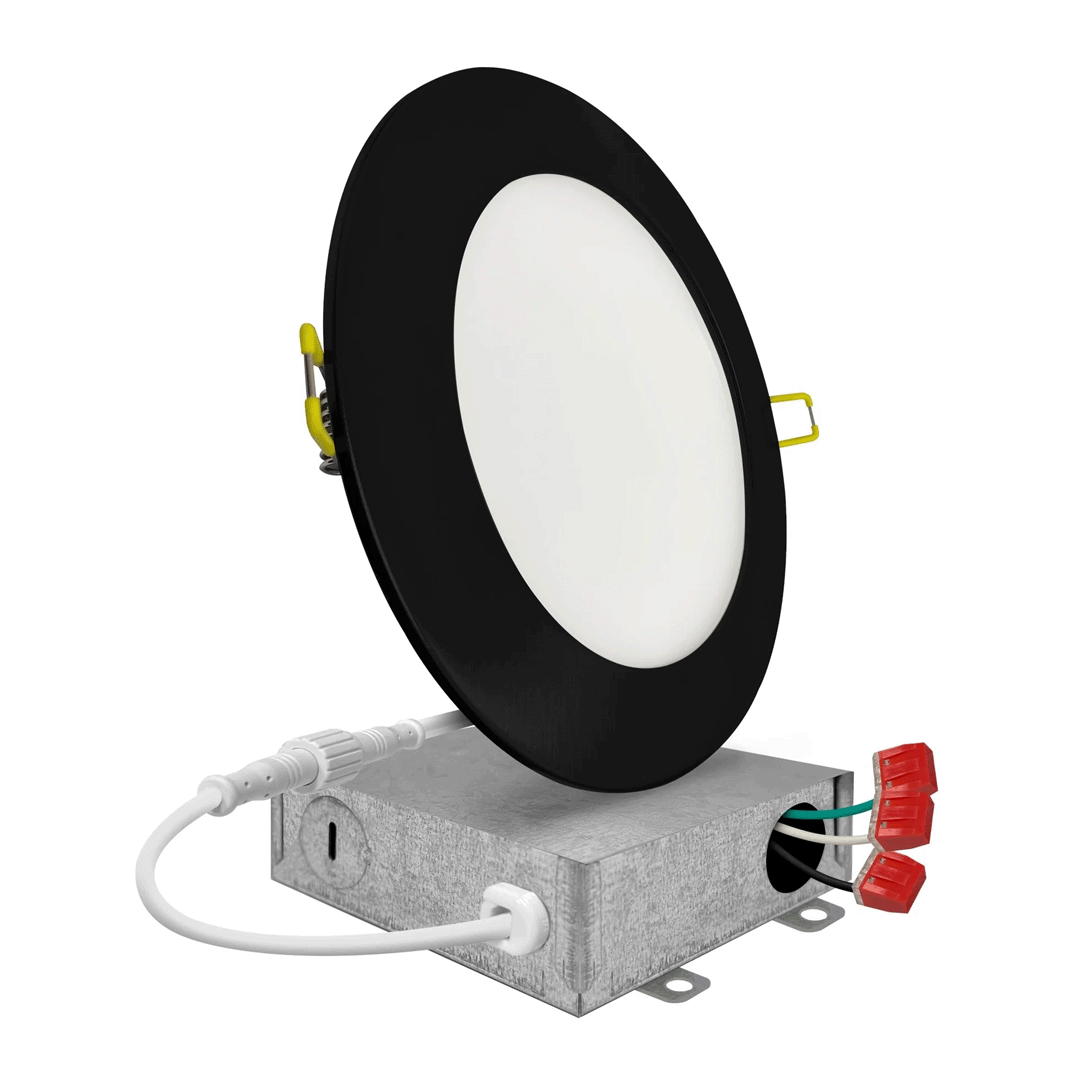

Canless recessed lighting, also known as wafer lights or slim lights, is a modern alternative to traditional recessed can lights. These ultra thin wafer downlights gained popularity in the late 2010s when homeowners and builders wanted to install recessed lighting in ceilings where can housing do not fit. Canless lights come with their own junction box, creating the signature LED ultra thin wafer look. LED wafer thin lights are much easier to install and have greater energy efficiency compared to lights that need cans.

FAQs

When comparing can vs canless recessed lighting, the main difference is the need for recessed cans. Unlike canless recessed lights, can fixtures can only go into existing recessed housing, which limits lighting design, since there is no way to move or adjust the layout of the lights. Canless wafer lights have the advantage of operating completely without recessed cans. Recessed canless lights get installed directly into any ceiling material with or without a recessed light mounting plate. Canless LED lights are also much thinner and connect directly to line voltage. These are the main overall differences between wafer lights vs can lights.

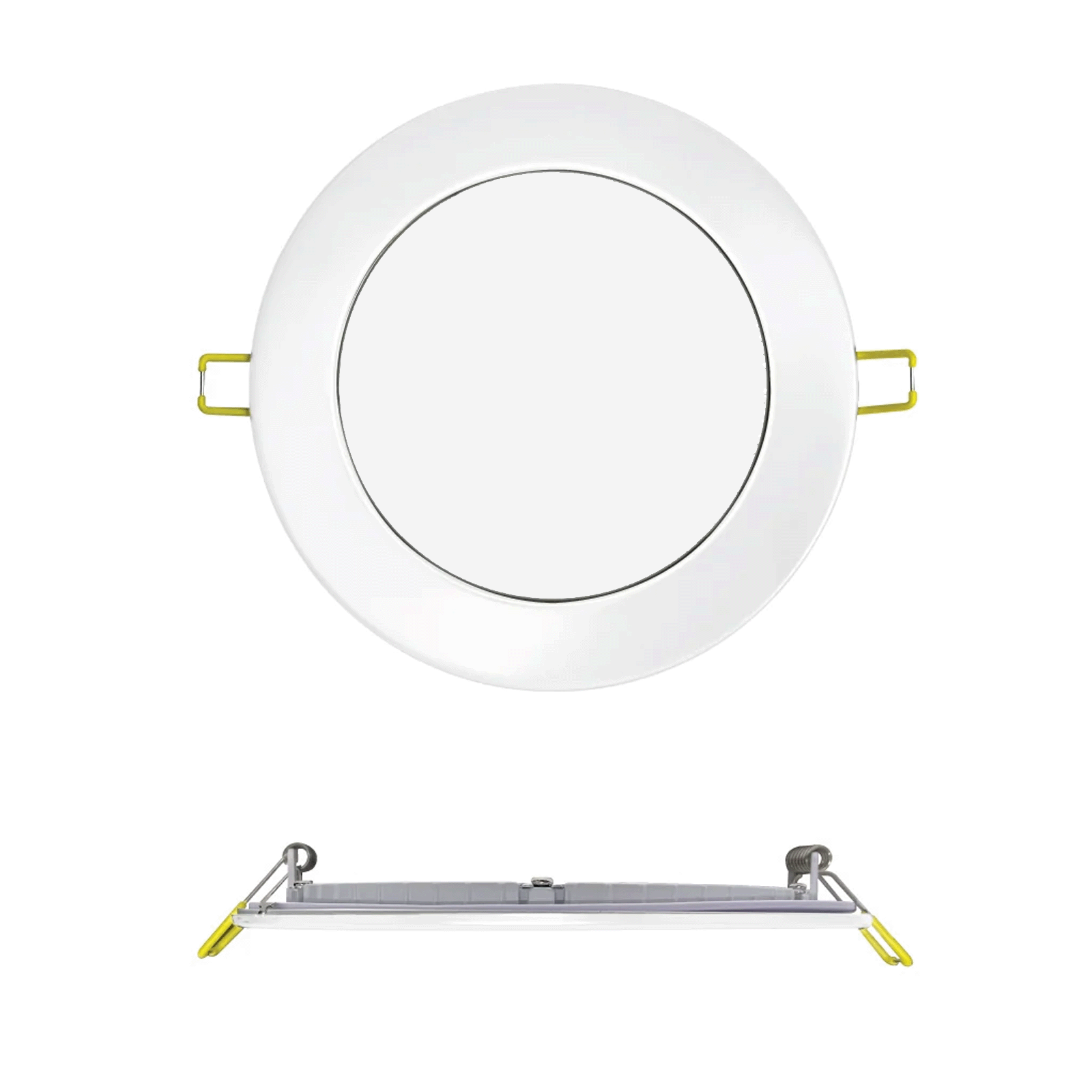

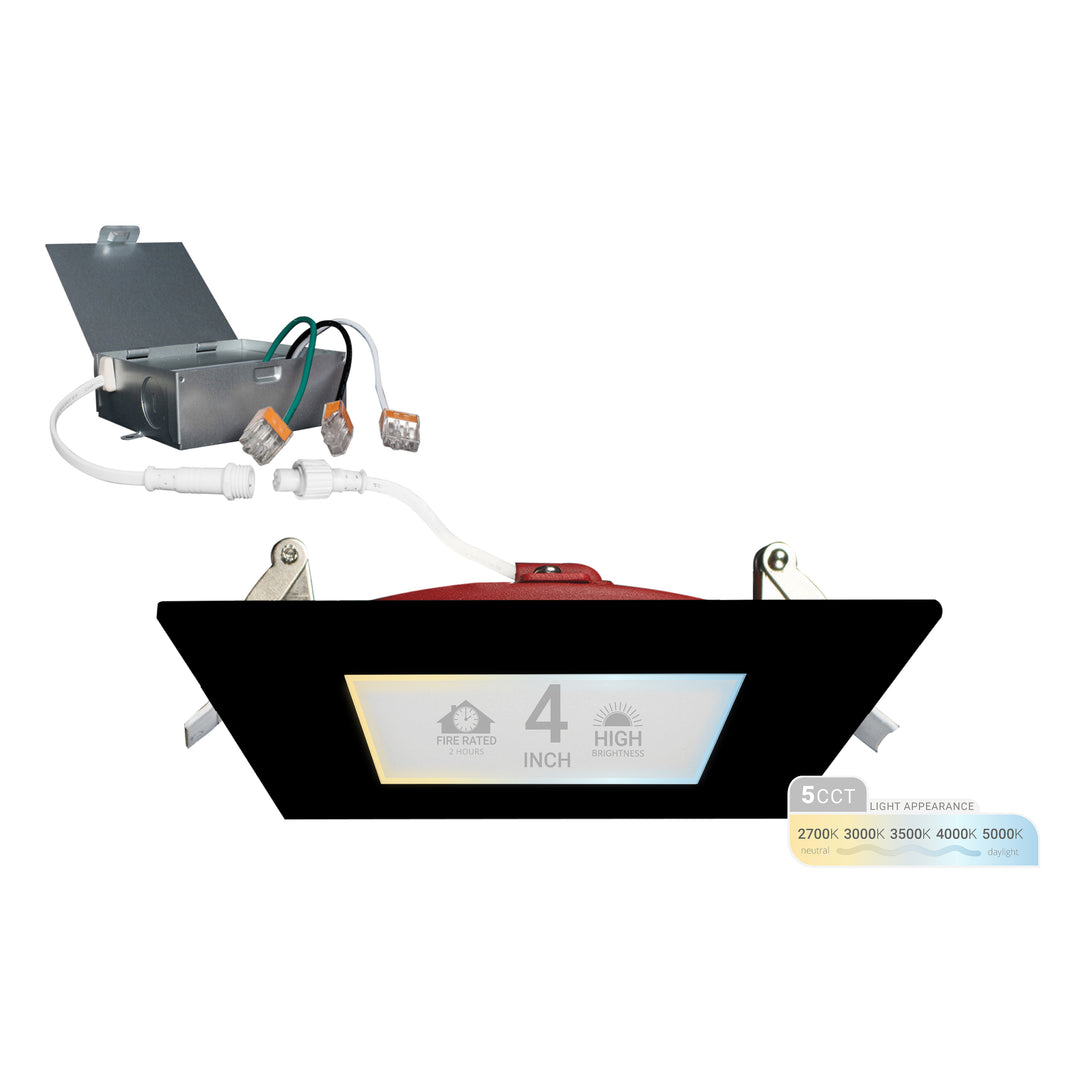

Installing canless LED lights is a straightforward 3-step process that typically takes about 15-30 minutes per fixture, including wiring.

Start the canless recessed lighting installation by turning off the power at the circuit breaker.

The next step is to cut a hole in the ceiling where the junction box and wafer recessed lights will go.

Next, wire the recessed fixture j-box to line voltage using push in connectors.

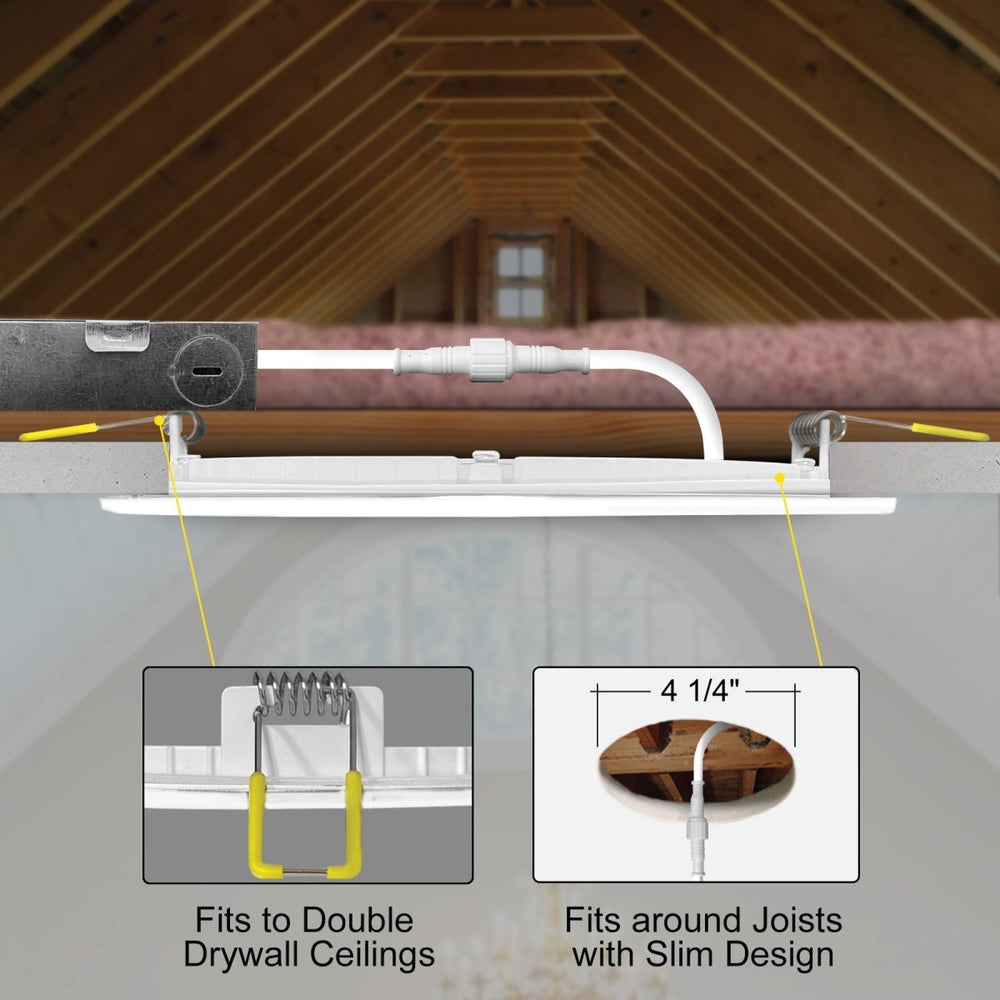

The last step is to place the canless downlight into the ceiling cutout, where a strong light clip will keep it in place. If you are installing around insultation, opt for for NuWatt wafer recessed lighting, which is IC rated and safe to install under joists. After mounting and securing the led slim light, you just restore power and test the installation

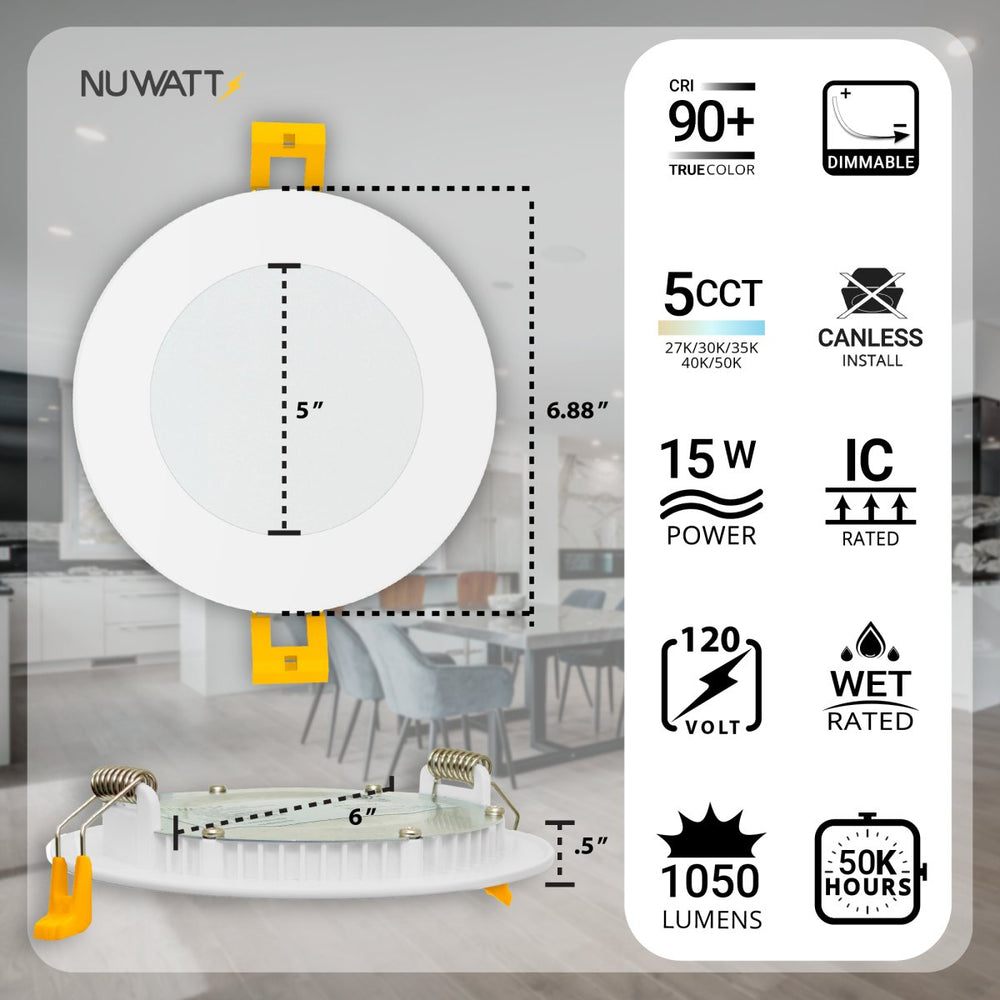

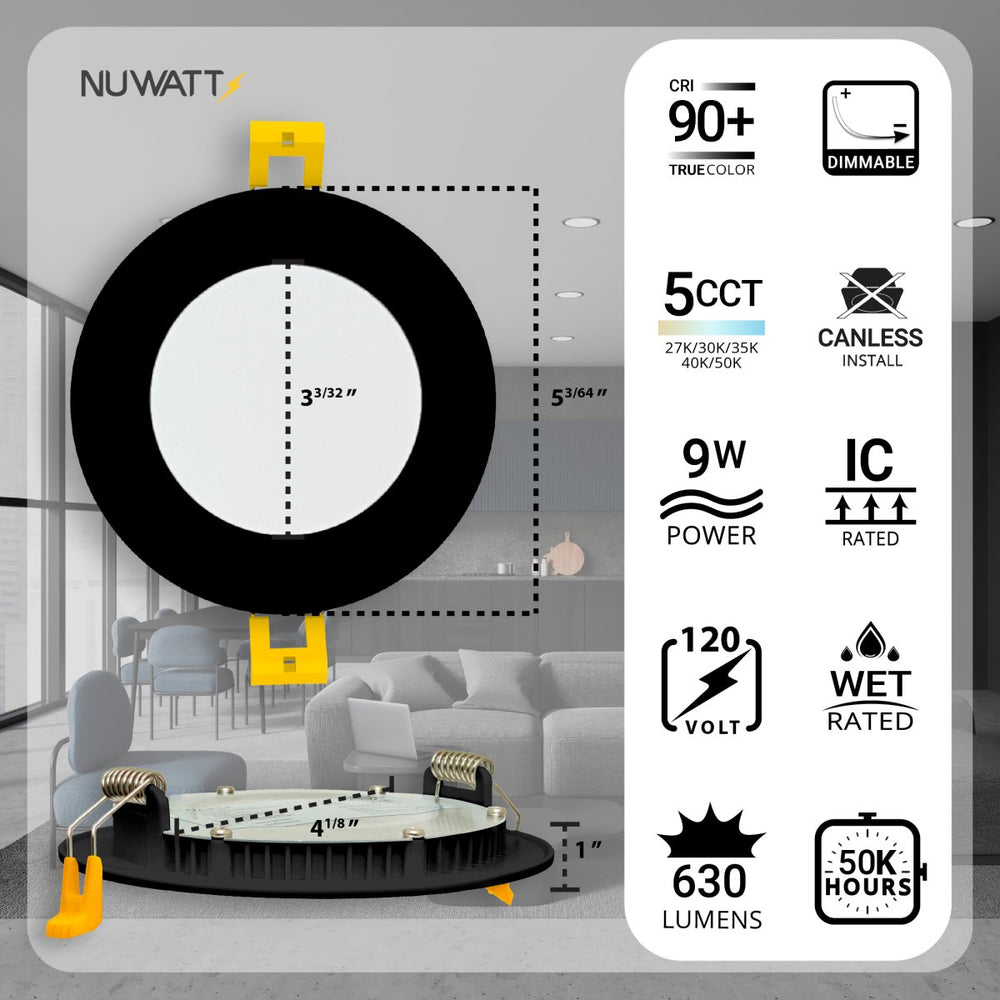

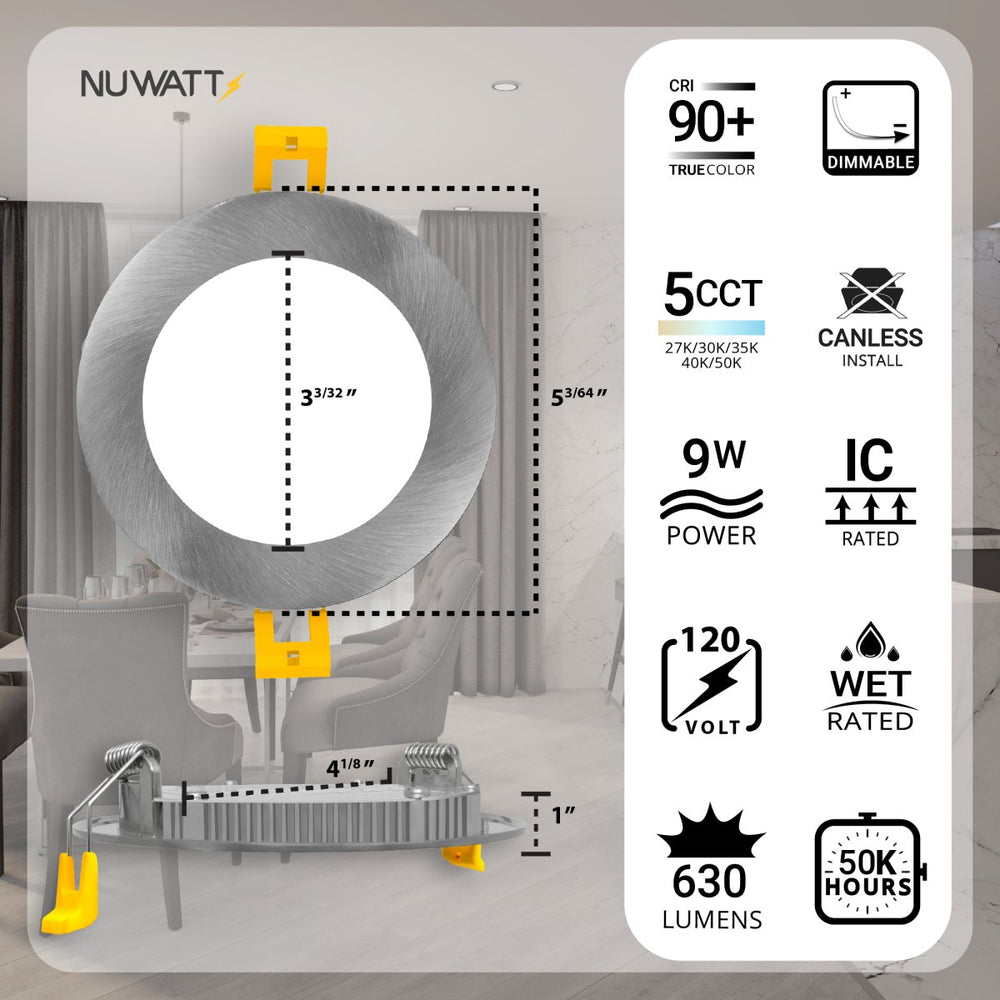

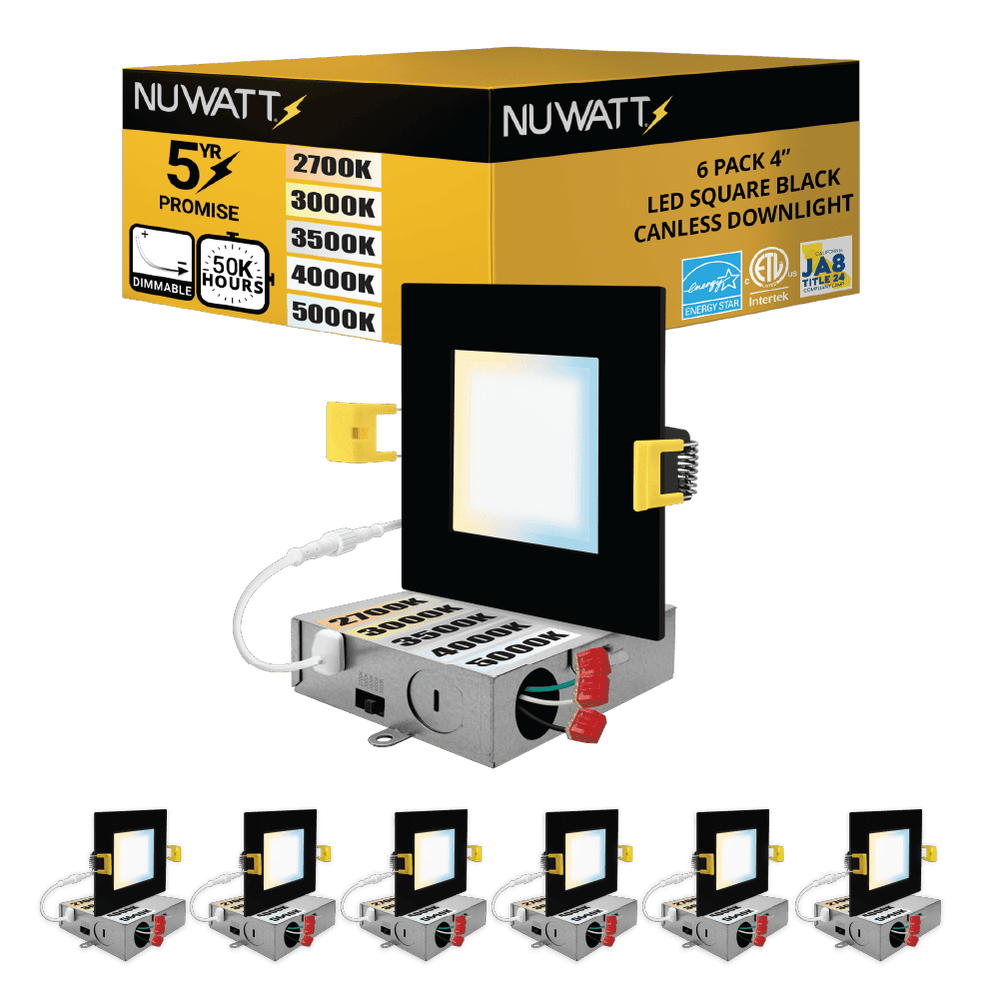

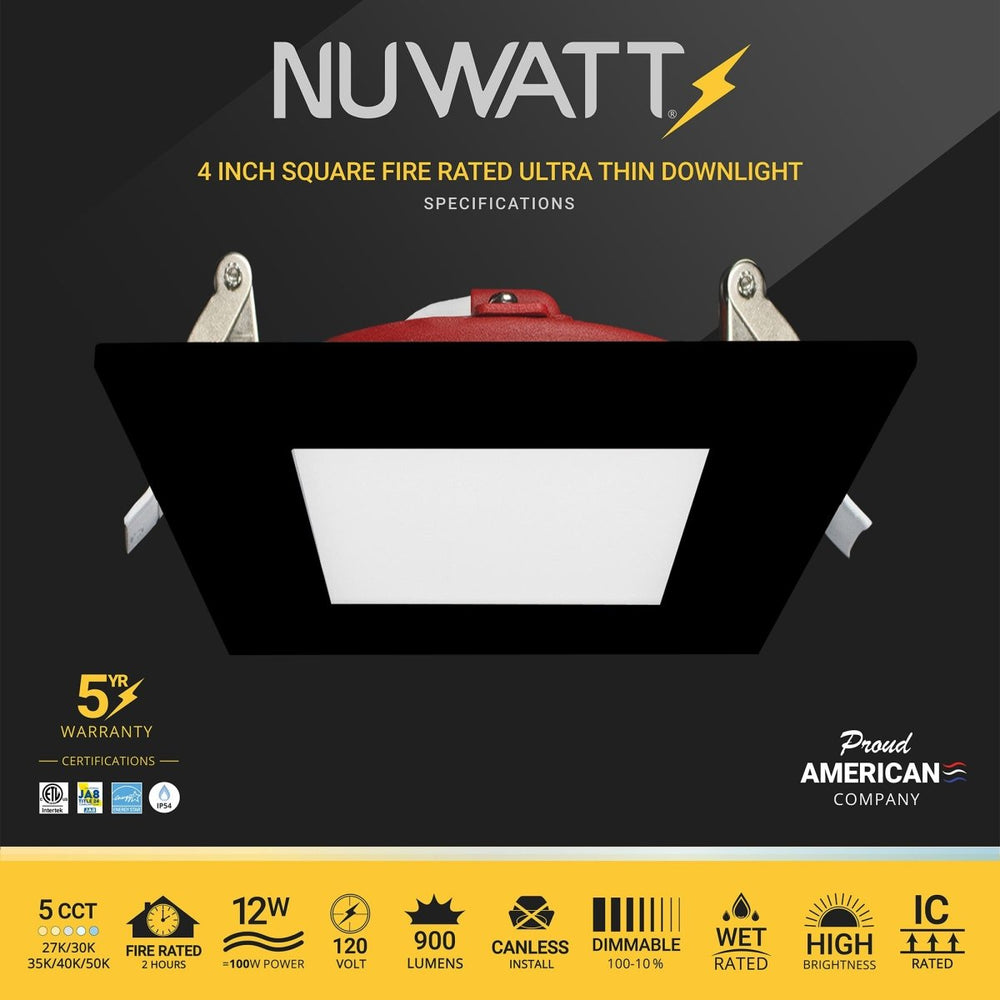

Local and national building codes require canless ceiling lights to be IC-rated, meaning they can safely come in direct contact with insulation. The main reason for this is to reduce the danger of fire, since ultra slim led pot lights generate heat that can become trapped by insulation. If a canless recessed light is not IC-rated, it must have a certain amount of clearance around it to avoid trapping heat. IC rated pot lights have built-in thermal protection to prevent overheating. NuWatt’s IC rated recessed wafer lights are airtight, helping the home to retain heat in the winter and cool air in the summer. NuWatt has the best slim recessed lighting on the market with a commitment to safety and regulatory compliance with our energy star, JA8, and ETL intertek certifications on each ultra thin recessed light.

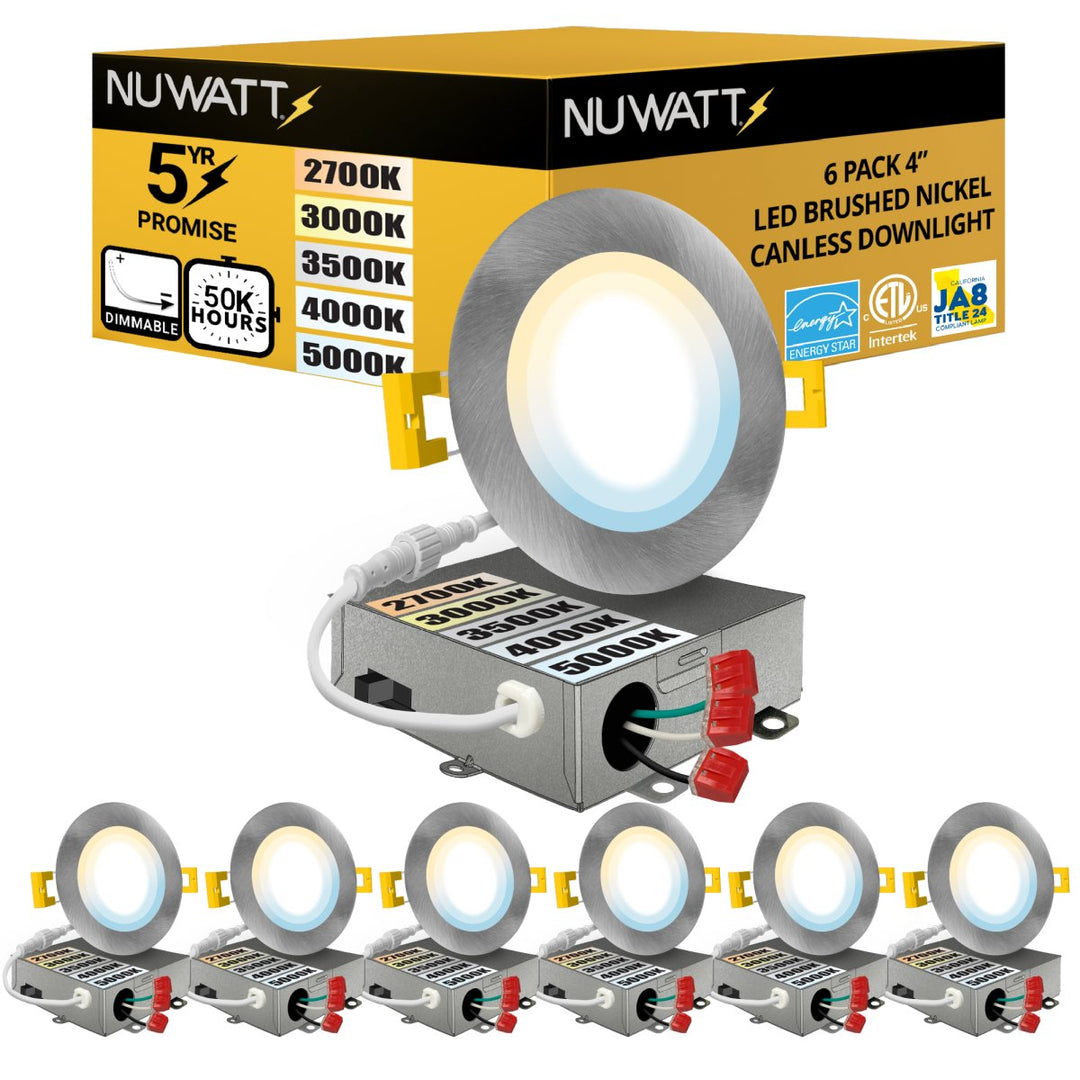

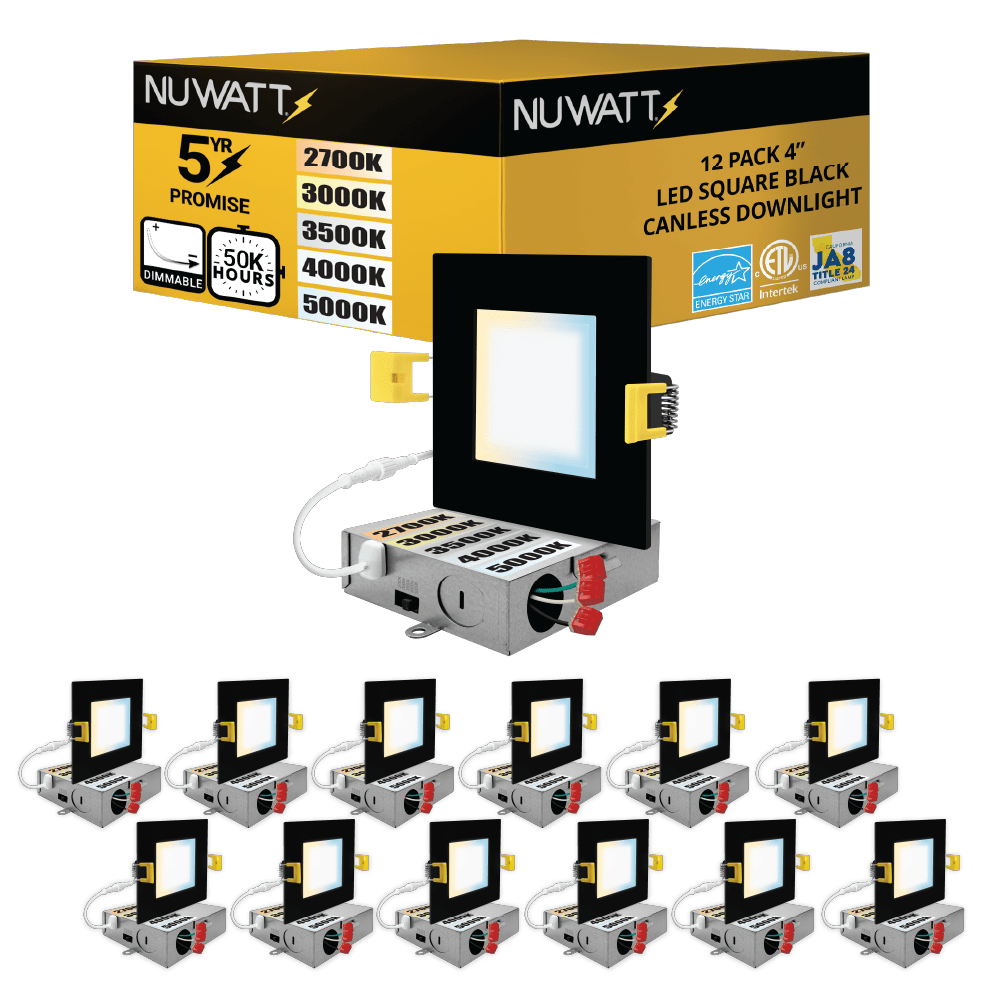

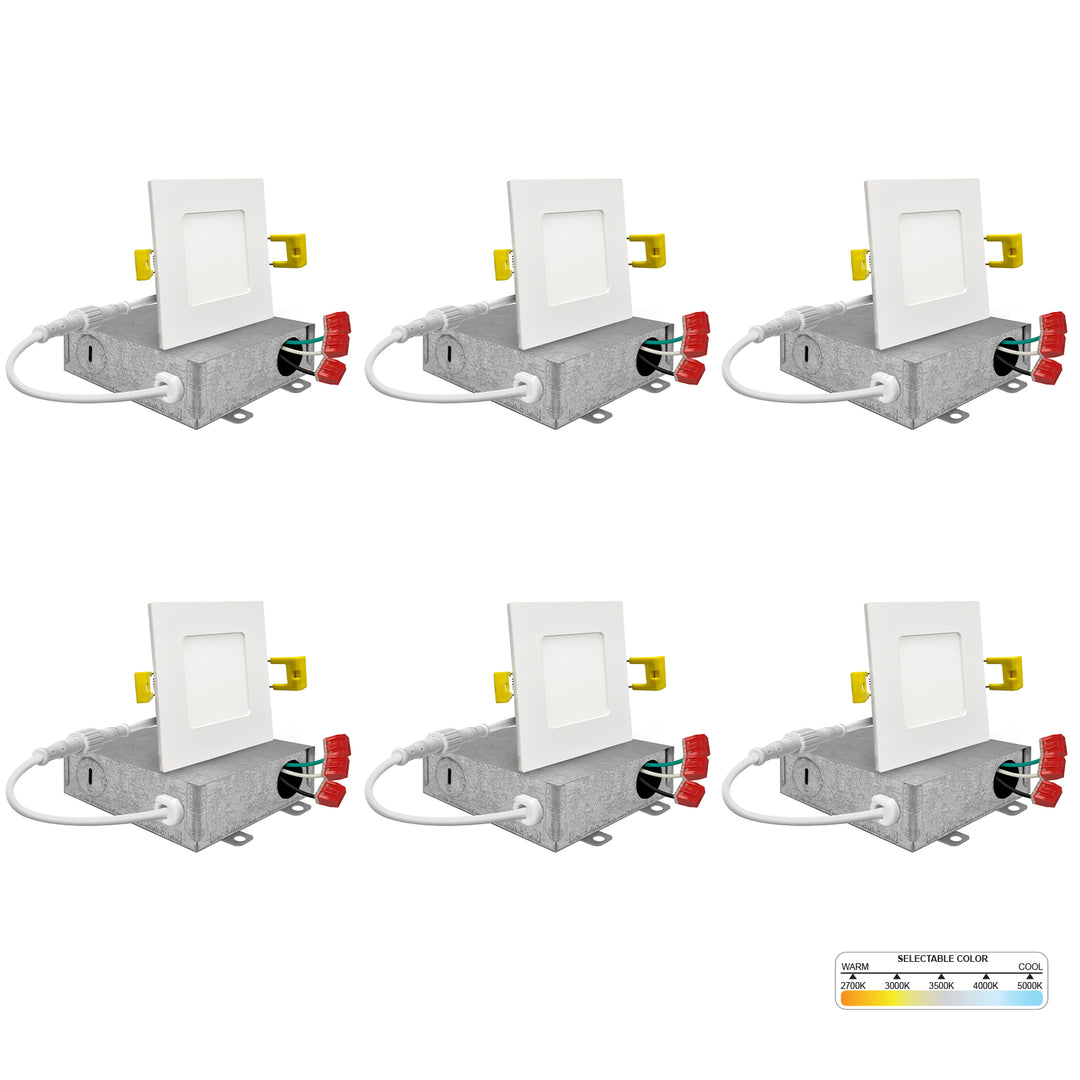

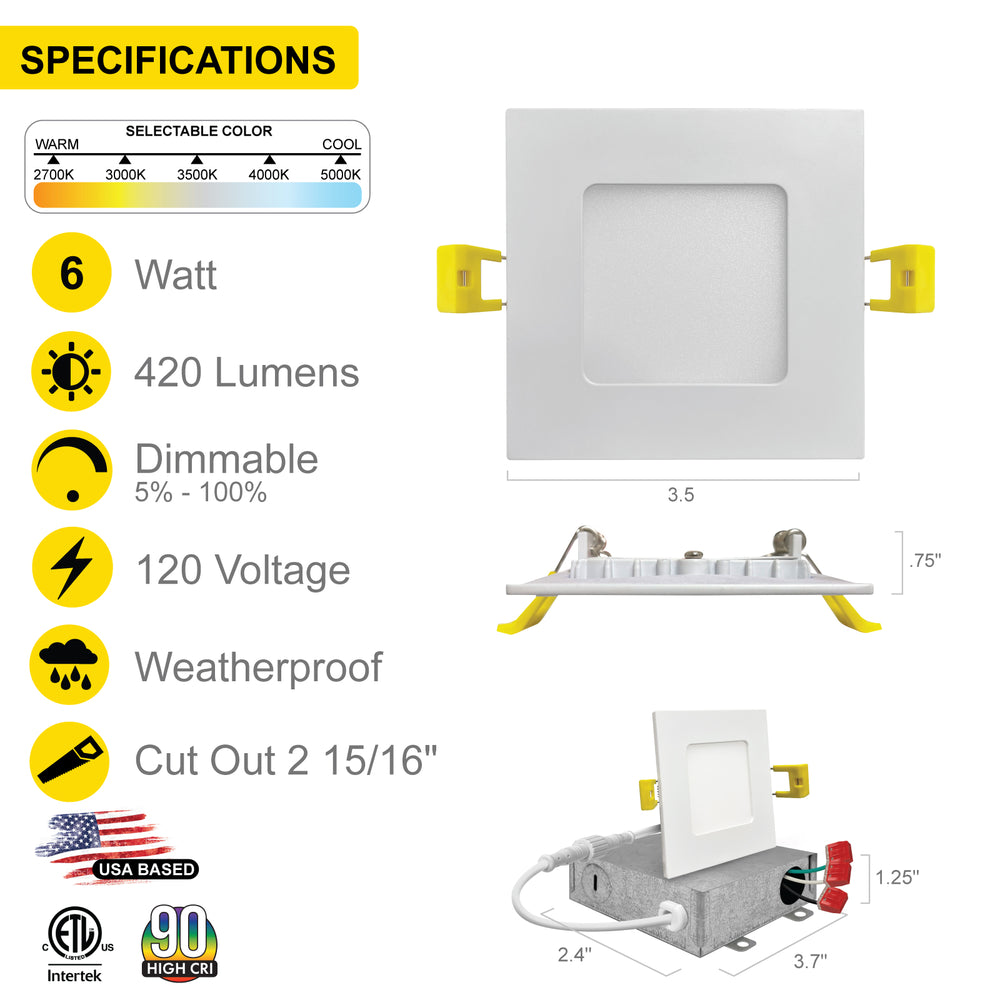

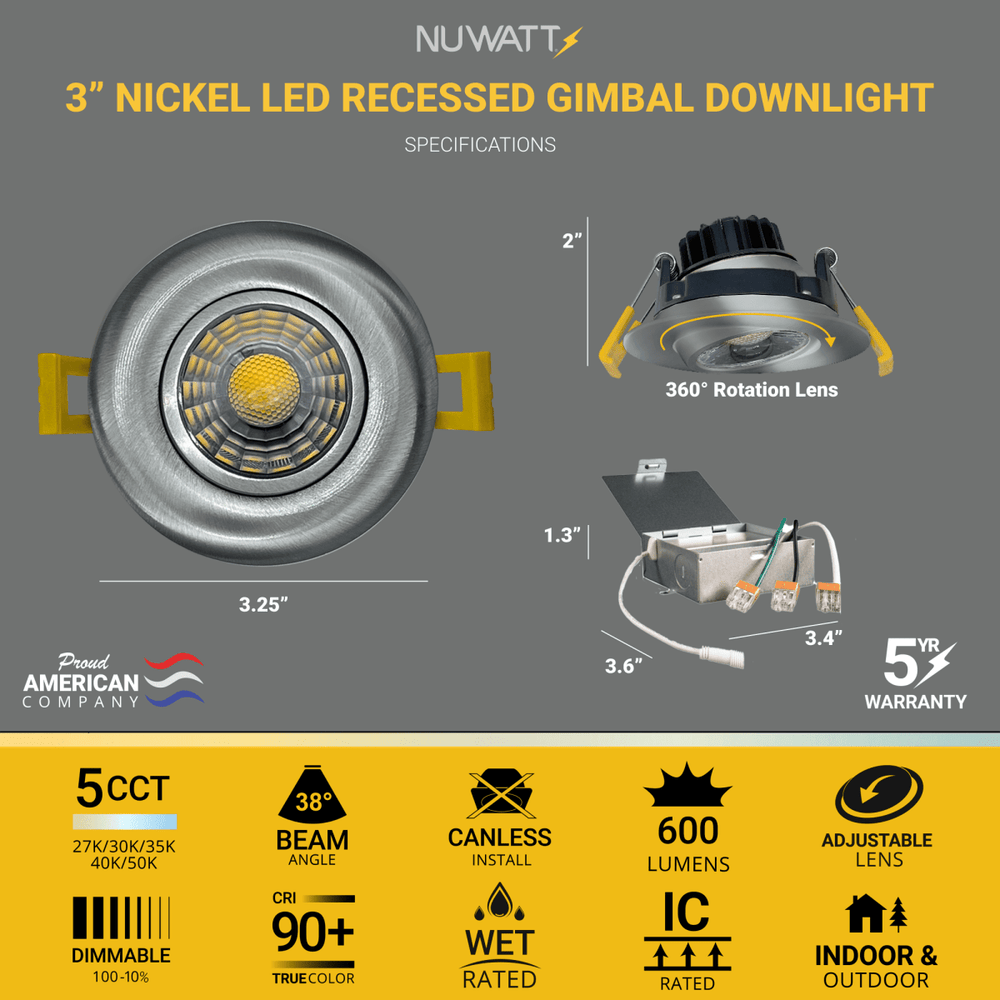

NuWatt offers a vast variety of canless lights to elevate any space. With your choice of a 3" wafer light, 4" wafer light or 6" wafer light sizes, plus black, bronze, and brushed nickel finishes, you are sure to find the right light to create perfect ambiance. For lighting vaulted ceilings, NuWatt canless gimbal LEDs help maintain even brightness throughout, while users looking for a high-end modern look can opt for NuWatt trimless canless recessed lighting. Beyond aesthetics, NuWatt wafer LED lightings stands out with Energy Star, JA8 and Intertek ETL certifications. Every NuWatt LED canless light comes with a 5 year guarantee and U.S. based customer service, giving homeowners peace of mind. With every light, NuWatt also delivers reliability, style, and adaptable ultra slim LED ceiiing light solutions tailored for every space.